DESIGNED TO IMPROVE INTAKE EFFICIENCY ON HIGHLY VISCOUS MEDIA

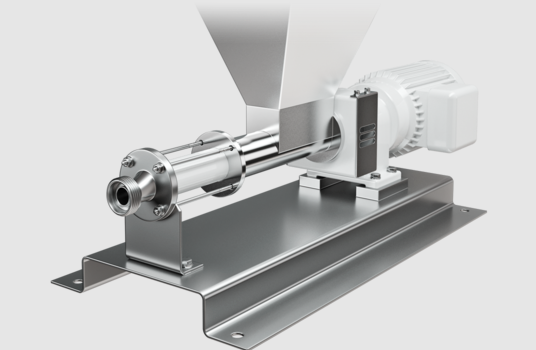

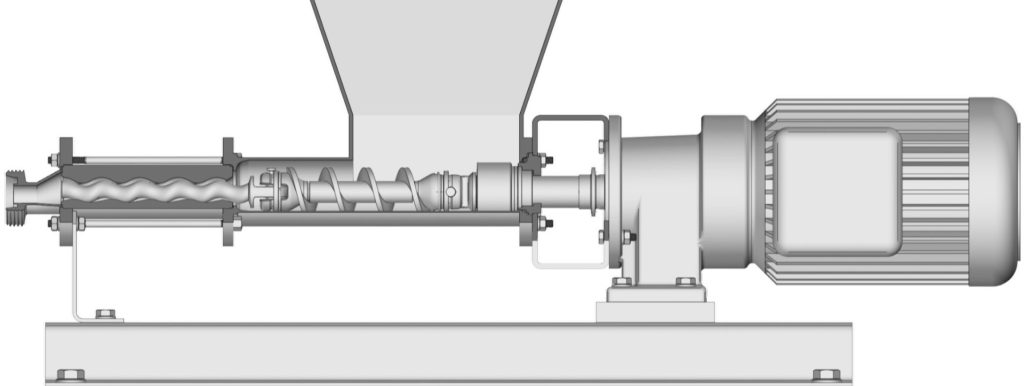

The MDTC range is the hygienic food grade version of the open hopper metering pump. It is used in a variety of applications in the food, beverage, pharmaceutical, and cosmetic industries to convey low to highly viscous media with low flowability. The pumps meet the highest hygienic requirements; adhering to 3-A Sanitary standards and have FDA approval.

Description of SEEPEX MDTC – Sanitary Open Hopper Metering Pump

The SEEPEX MDTC is a high-performance sanitary metering pump designed for use in a wide range of industries, including food and beverage, pharmaceuticals, and cosmetics. With its open hopper design, the pump is ideal for handling viscous liquids, slurries, and pastes with high solids content.

Constructed from FDA-compliant materials, the MDTC meets the strictest hygiene standards and can be easily cleaned and sanitized. The pump features an adjustable flow rate and is capable of handling pressures up to 8 bar, making it suitable for a variety of applications.

The pump’s robust construction and reliable performance make it a popular choice for demanding industrial applications. Whether you need to transfer viscous food products, dispense precise amounts of pharmaceutical ingredients, or handle abrasive substances in the cosmetics industry, the SEEPEX MDTC is a versatile and dependable solution.

Applications of SEEPEX MDTC – Sanitary Open Hopper Metering Pump

The SEEPEX MDTC is a versatile metering pump that can be used in a wide range of applications. Its open hopper design and ability to handle high solids content make it ideal for the food and beverage industry, where it can transfer viscous liquids, sauces, and purees. In the pharmaceutical industry, the pump’s precise flow control is essential for dispensing accurate amounts of active ingredients during production.

The pump’s robust construction also makes it suitable for handling abrasive substances, such as exfoliants, in the cosmetics industry. Additionally, the MDTC’s ability to handle shear-sensitive products, such as emulsions and creams, without damaging their structure makes it a valuable tool for cosmetic manufacturers.

Overall, the SEEPEX MDTC is an important asset for any industry that requires precise, reliable metering of fluids or pastes with high solids content.

Energy and time savings

Compression zone increases capacity of conveying chamber resulting in process time and energy savings

No vapor locking

Cavity design allows for conveyance of liquids, solids, and gases

Ease of operation

Valveless flow control for ease of operation

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Easy maintenance

Simple and predictive maintenance due to minimal components

Residue-free cleaning

Residue-free cleaning through Clean-in-Place (CIP) continuous cleaning

People Also Ask