W – WOBBLE PUMP

Economical, space-saving, easy to maintain – SEEPEX wobble pumps with compact block design have a rotating unit with just one joint. They are made to “wobble” by a flexible stator fixed on one side. They are used in virtually all branches of industry to pump liquids of various viscosities – even containing high levels of solids.

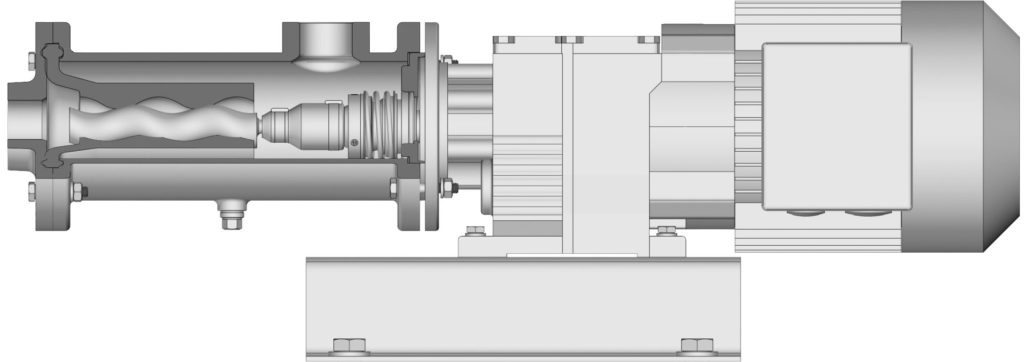

The Description of SEEPEX W – Wobble Pump

SEEPEX W – Wobble Pump is a type of positive displacement pump that operates through the use of an eccentrically mounted rotor. As the rotor rotates, it creates a wobbling motion that causes the elastomeric stator to flex and move fluid along the pump’s flow path.

One of the key benefits of the SEEPEX W – Wobble Pump is its ability to handle difficult-to-pump fluids with high viscosity, solids content, or shear sensitivity. This makes it an ideal choice for applications in industries such as food processing, wastewater treatment, and chemical manufacturing.

In addition to its superior pumping capabilities, the SEEPEX W – Wobble Pump also offers easy maintenance and long service life. The simple design and minimal number of components allow for quick and easy disassembly, while the robust construction ensures reliable operation even in harsh environments.

Overall, the SEEPEX W – Wobble Pump is an efficient and reliable option for a wide range of pumping applications, providing superior performance and low total cost of ownership.

Applications of SEEPEX W – Wobble Pump

The SEEPEX W – Wobble Pump is a versatile pumping solution that can be used in a wide range of applications, thanks to its ability to handle challenging fluids with high viscosity, solids content, or shear sensitivity. Some common applications for the SEEPEX W – Wobble Pump include:

- Food processing: The pump is ideal for handling viscous and abrasive food products, such as fruit and vegetable purees, dairy products, and meat slurries.

- Wastewater treatment: The SEEPEX W – Wobble Pump can effectively handle sludge, biosolids, and other difficult-to-pump wastewater materials, making it a popular choice for municipal and industrial sewage treatment plants.

- Chemical manufacturing: The pump’s ability to handle aggressive chemicals and high-viscosity fluids makes it well-suited for use in chemical processing applications, including the transfer of adhesives, resins, and polymers.

- Oil and gas: The SEEPEX W – Wobble Pump is commonly used in upstream oil and gas operations to handle drilling muds, cement slurries, and other fluids with high solids content.

Overall, the SEEPEX W – Wobble Pump is a reliable and efficient choice for a variety of industries and applications, providing superior performance and long service life.

Easy maintenance

Quick and simple replacement of the conveying elements due to rotating unit attached with only one joint

Space-saving

Low space requirements thanks to short, compact design without a protective frame and with a directly flange-mounted drive (block type)

Reduced operating costs

Minimal maintenance costs and downtime thanks to quick replacement of conveying elements

Budget-friendly

Low procurement costs due to compact design

High-quality

Fulfills even the strictest quality standards thanks to robust design with wobble stators and containment cup design

People Also Ask