Small Scale Progressive Cavity Pumps for Accurate Dosing

What is a Small Scale Progressive Cavity Pump for Accurate Dosing?

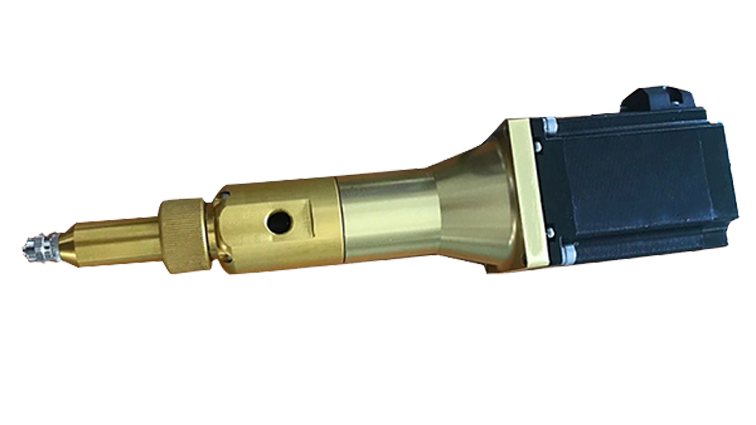

PMS Pump has launched a new small-scale progressive cavity pump(progressive pump) designed specifically to enable the precise dosing of fluids and pastes proportionate to the rotational speed.

The maximum filler content is 60%. The dosing can be set to be absolutely linear, and the dosing accuracy and repeatability should not exceed 1%.

The Small Scale Progressive Cavity Dosing Pump can deliver repeatable and accurate flow up to within ± 1%. Unlike a centrifugal pump that “throws” the fluid away from the impeller vanes, a progressive cavity pump enables the fluid to move from one cavity to the next, “pushing” the fluid forward.

The pump is a low flow progressing cavity pump.The new technology, which utilizes small progressive cavity pump such as progressive cavity metering pump, is based on the volumetric principle of an endless or infinite piston. In this system, the rotor and stator components work together to form a sealed metering chamber, ensuring that there is no leakage. The eccentric movement of the rotor in these pumps allows for a low-shear motion of the medium from one chamber to the next, which is important to prevent any damage to the media being pumped.

Small Scale Progressive Cavity Pump Features

The progressive cavity pump viscosity range consists of two parts: driving unit and conveying unit. It is equipped with a needle nozzle and a pump whose liquid output is controlled by a control system.

The small progressive cavity pump rpm realizes the medium conveying function through the directional rotation of the rotor in the stator cavity.

The transportation process does not have any influence on the medium performance.

At the same time, the reverse rotation of the motor can easily realize the function of medium progressive cavity pump suction, ensuring the cleanness of medium and materials, no dripping and no pollution!

The progressive cavity pump viscosity range is a revolutionary product of viscous flow precision micro-transportation, with a minimum flow rate of 0.001ml and an accuracy of 1%. It has the unique advantages of constant flow rate,accuracy of progressive cavity pump being able to suck back, being suitable for granular media, and the flow rate is not affected by changes in viscosity and pressure. It is widely used for precise quantitative transportation, gluing and potting of various fluids.

Small Scale Progressive Cavity Pump

- Save 30% of glue usage.

- The minimum flow rate can reach 0.001ml, and the accuracy is 1%.

- With suck-back function, the problems of medium dripping and drawing are completely avoided.

- Self-sealing function of minimum 2Bar (increasing with viscosity of medium).

- The metering pressure can reach 16-20 bar.

- It can be used with very small glue nozzle or needle nozzle for high-precision glue delivery.

- Self-priming function (suitable for high viscosity medium).

- There is no need to install any pressure tank device for the self-flowing medium.

- Volumetric transportation with constant flow rate (not affected by external factors).

- The driving and pump body parts are isolated from each other.

- Modular design, easy to install, use, clean and maintain.

- Quick connector design, easy to adjust according to field requirements.

Progressive Cavity Pump Advantages

Progressive cavity pumps offer precise flow control, gentle handling of fluids, the ability to handle viscous and abrasive substances, self-priming capability, and efficient operation. These advantages make them a preferred choice in industries such as food and beverage, oil and gas, chemical processing, and wastewater treatment.

Micro dispensing progressive cavity pump parameter list

| Model | Allowable speed | Optimum speed | Recommended dispensing flow | Dispensing pressure | Starting torque |

|---|---|---|---|---|---|

| 0.5 CC | 12~300 rpm | 15~60 rpm | 0.13~0.5 ml/s | 24 bar | ≥ 10 Nm |

| 1.5 CC | 12~300 rpm | 15~60 rpm | 0.38~1.5 ml/s | 18 bar | ≥ 10 Nm |

| 3 CC | 12~300 rpm | 15~60 rpm | 0.75~3 ml/s | 18 bar | ≥ 16 Nm |

| 6 CC | 12~300 rpm | 15~60 rpm | 1.5~6 ml/s | 18 bar | ≥ 20 Nm |

| 12 CC | 12~300 rpm | 15~60 rpm | 3~12 ml/s | 18 bar | ≥ 30 Nm |

| 24 CC | 12~300 rpm | 15~60 rpm | 6~24 ml/s | 18 bar | ≥ 50 Nm |

| 48 CC | 12~300 rpm | 15~60 rpm | 12~48 ml/s | 18 bar | ≥ 100 Nm |

| 96 CC | 12~300 rpm | 15~60 rpm | 24~96 ml/s | 18 bar | ≥ 200 Nm |

| 200 CC | 12~300 rpm | 15~60 rpm | 50~200 ml/s | 18 bar | ≥ 400 Nm |

It can be equipped with servo motor or stepping motor;

Support customized small stator and rotor;low flow progressive cavity pump;pump scale

Small Scale Progressive Cavity Pump Parameter Table

| ml/per revolution | 0.004 | 0.012 | 0.05 | 0.15 | 0.3 | 0.75 | 1.5 |

| Flow per revolution | 0.003 ml/r | 0.01 ml/r | 0.06 ml/r | 0.2 ml/r | 0.4 ml/r | 1 ml/r | 1.6 ml/r |

| Adjustable dosing flow range | 0.04~0.4 ml/min | 0.15~1.5 ml/min | 0.5~6.0 ml/min | 1.5~15 ml/min | 3~30 ml/min | 8~75 ml/min | 15~150 ml/min |

| Motor min and max (rpm) | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 |

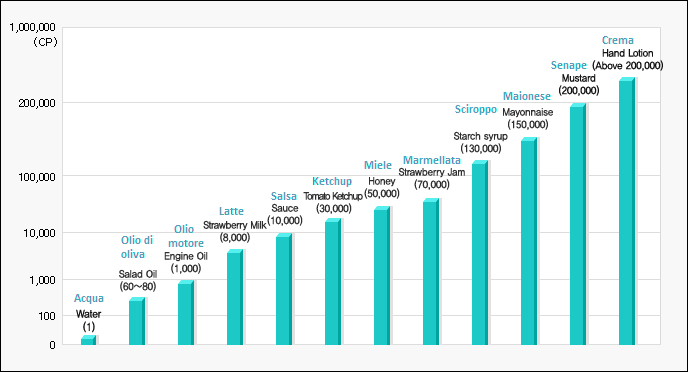

| Recommended fluid viscosity min and max | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps | 0-1,000,000 cps |

| Input Connection | 1/8″ | 1/8″ | 1/8″ | 3/8″ | 1/2″ | 1/2″ | 1/2″ |

| Input min and max pressure | 0-6 bar | 0-6 bar | 0-6 bar | 0-6 bar | 0-6 bar | ≤2.0 mpa | ≤2.0 mpa |

| Output Connection | luer lock with 0 ring | luer lock with 0 ring | luer lock with 0 ring | luer lock with 0 ring | 1/4″ | 1/4″ | 1/4″ |

| Output max pressure | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar | 16~20 bar |

| Rotor material | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al |

| Stator material | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM | FKM; NBR; EPDM; HNBR; FFKM |

| Wetted part of body material | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al | SUS304; SUS316L; Al |

| Weight | 350g | 350g | 400g | 500g | 2300g | 2800g | 3000g |

Medium Viscosity Chart

Small Scale Progressive Cavity Pumps Progressive Cavity Pump Applications

A progressive cavity metering pump is a type of pump that can accurately and consistently transfer high viscosity fluids and chemical substances. It operates by producing a spiral motion through a unique combination of rotor and stator, which drives the flow of liquid. This pump finds extensive use in industries such as chemical, petroleum, food, and pharmaceutical, and is capable of precise flow and pressure control, as well as transferring high viscosity, volatile, and corrosive liquids.

All kinds of solvents, adhesives, paints, chemical materials, glue stick, etc., including silica gel, EMI conductive adhesive, UV adhesive, AB adhesive, dry glue, epoxy adhesive, sealant, hot adhesive, grease, silver adhesive, red adhesive, solder paste, heat dissipation paste, anti-soldering paste, transparent paint, screw fixative, woodworking adhesive, anaerobic adhesive, acrylic adhesive, anti-wear adhesive and crystal glue.

The micro-dispensing system composed of dispensing pump Preeflow is suitable for various fields of industrial production: mobile phone keys, printing, switches, connectors, computers, digital products, digital cameras, MP3, MP4, electronic toys, speakers, buzzers, electronic components, integrated circuits, circuit boards, LCD screens, relays, speakers, crystal oscillator components, LED lamps, chassis bonding, optical lenses, mechanical parts sealing.

When to use progressive cavity pumps

Progressive cavity pumps are used when there is a need to efficiently handle fluids with high viscosity, shear sensitivity, solids content, or abrasive properties. They are commonly employed in various industries such as oil and gas, wastewater treatment, chemical processing, and food production.

How do progressive cavity pumps work?

Progressive cavity pumps work by using a rotating screw-shaped rotor within a stationary helical stator. As the rotor turns, cavities are formed between the rotor and stator surfaces, trapping and displacing fluid from the inlet to the outlet. This displacement action creates a steady and pulsation-free flow, making progressive cavity pumps effective for handling viscous fluids and providing precise flow control.

People also ask :

Our engineers will help you to choose equipment in accordance with your requirements.