What is PMS Progressing Cavity Pumps Manufacturers?

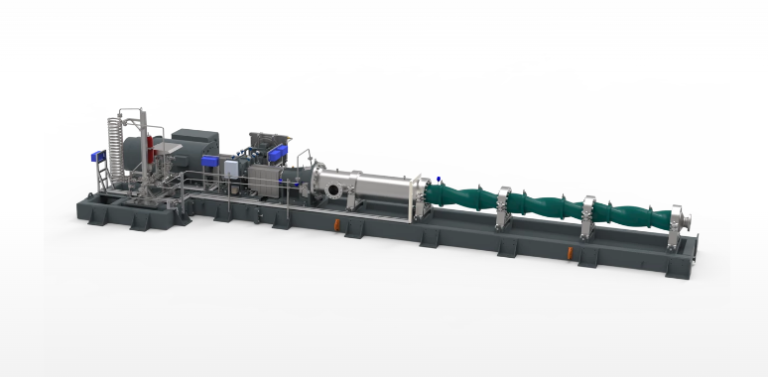

PMS Pump Manufacture Co., Ltd was founded in 2003, is a professional pump enterprise integrating research, development, production, sales and service.

Since its inception, quality management has always been the first goal.Therefore, we have designated staff responsible for raw material composition inspection, pump case bulge test, performance test, and appearance examination.

Some famous progressive cavity pump manufacturers

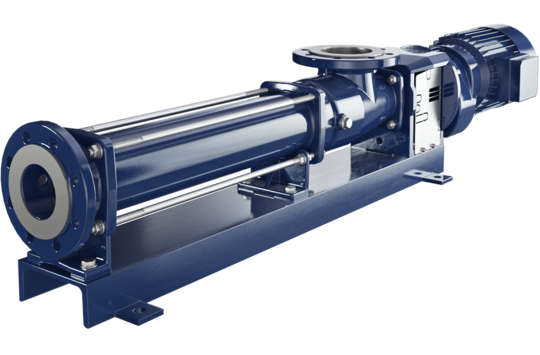

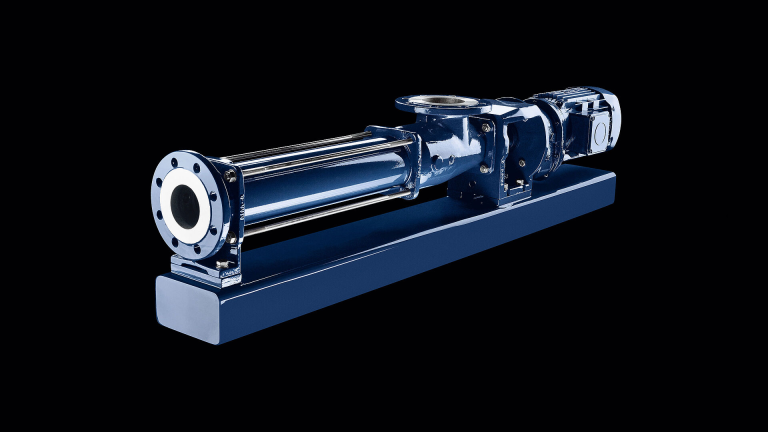

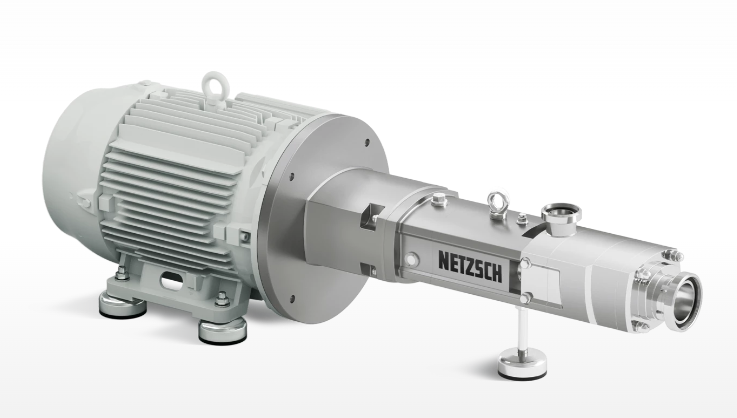

PMS is a professional progressing cavity pump manufacturers. The main production of brand has Netzsch, Seepex, Moyno, Mono, brands such as a replacement pump.

We can also OEM screw pump according to customer’s needs.

How does a progressive cavity pump work?

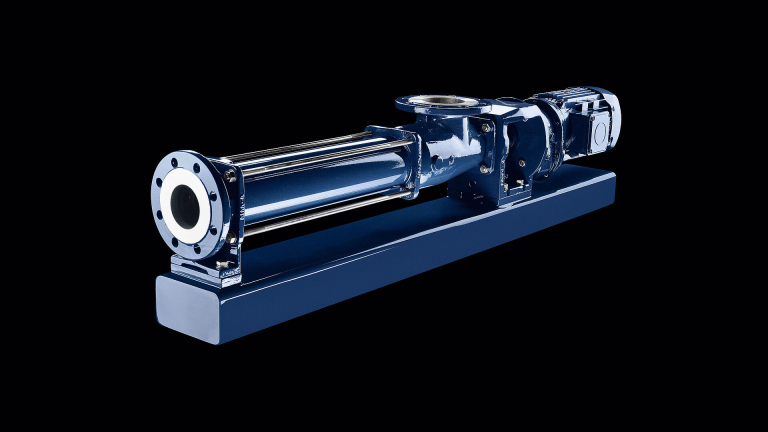

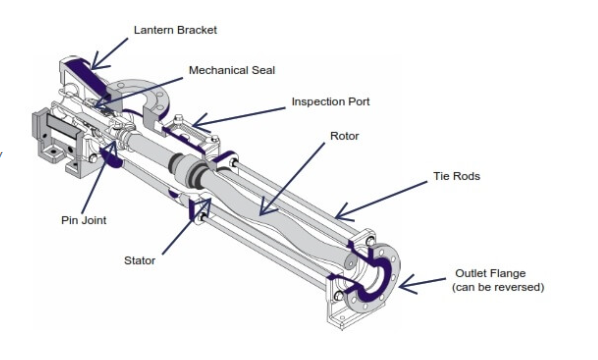

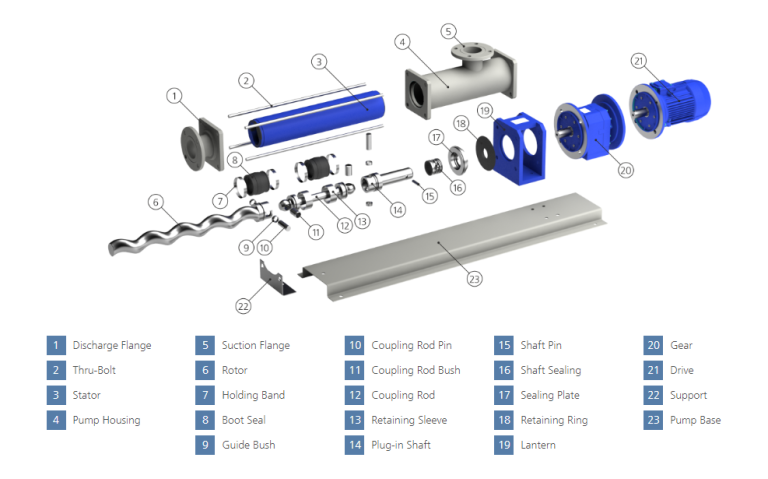

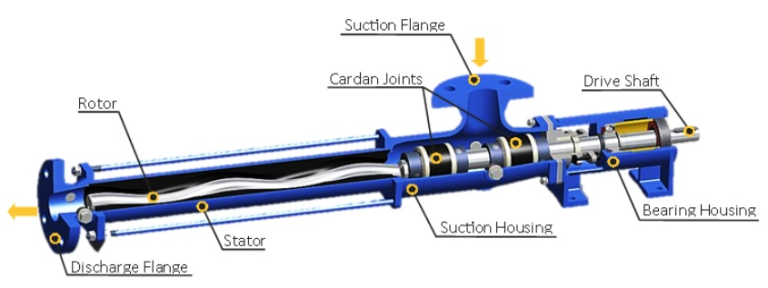

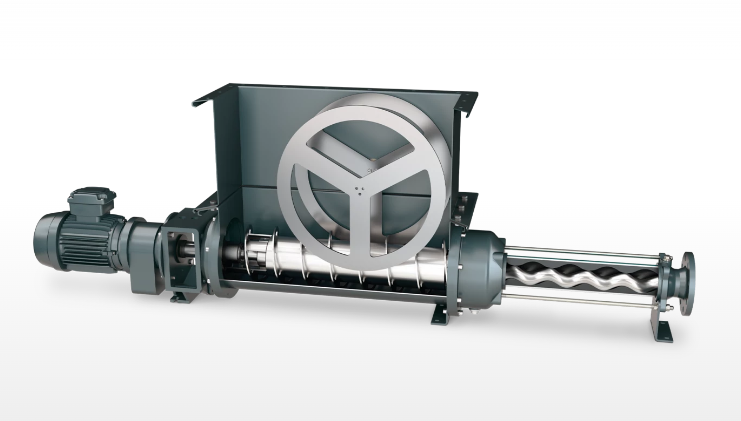

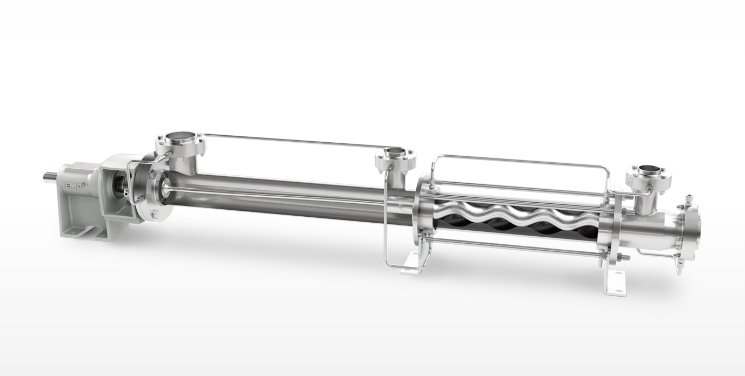

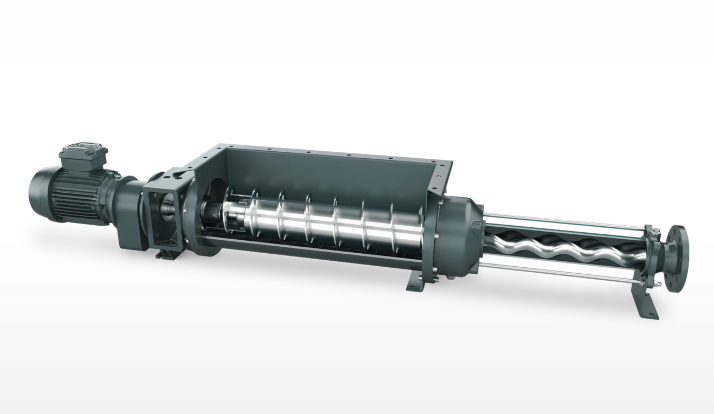

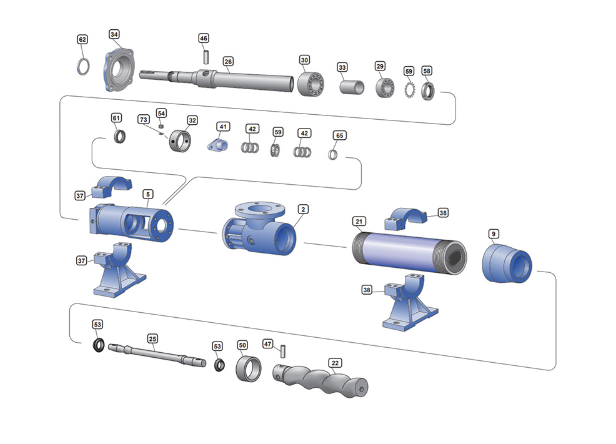

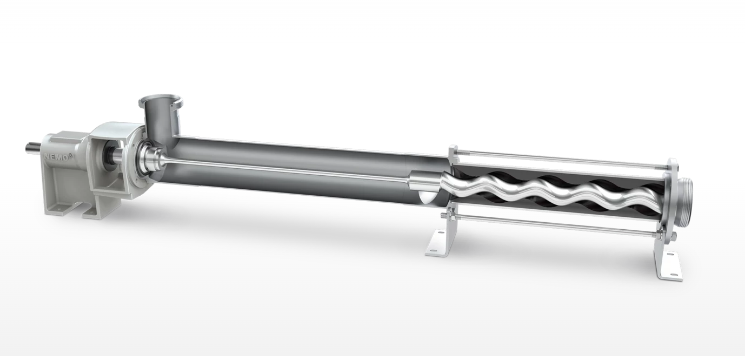

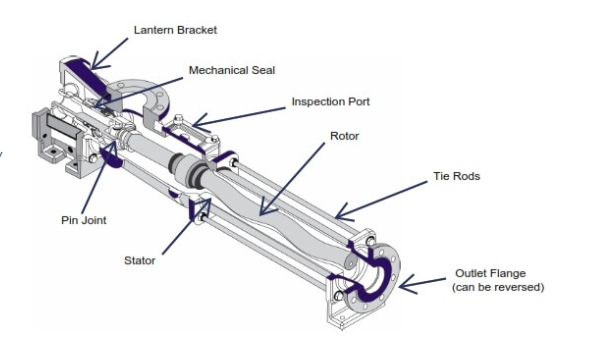

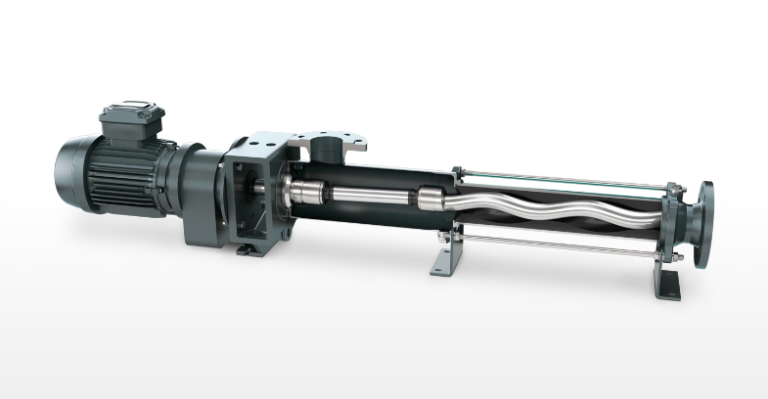

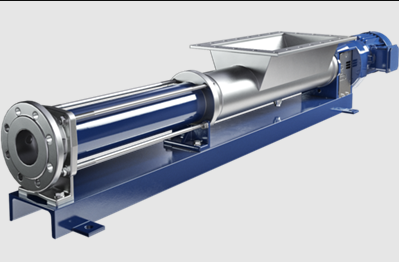

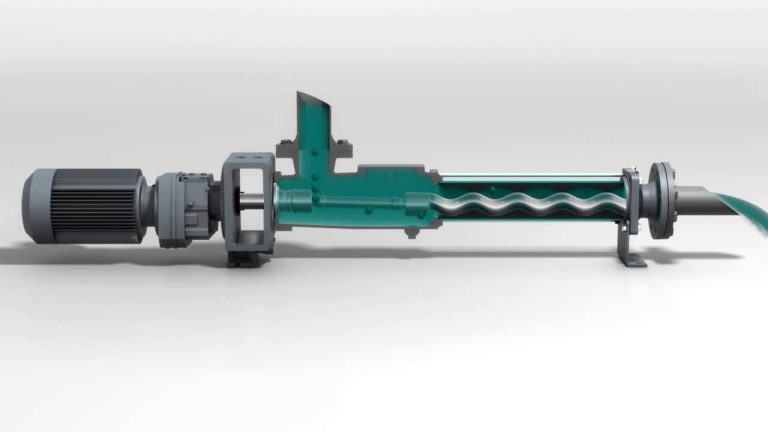

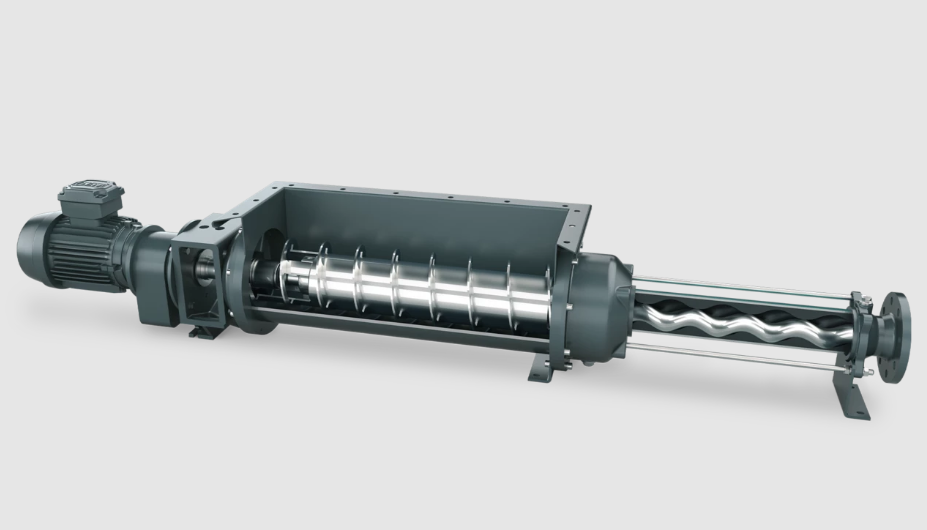

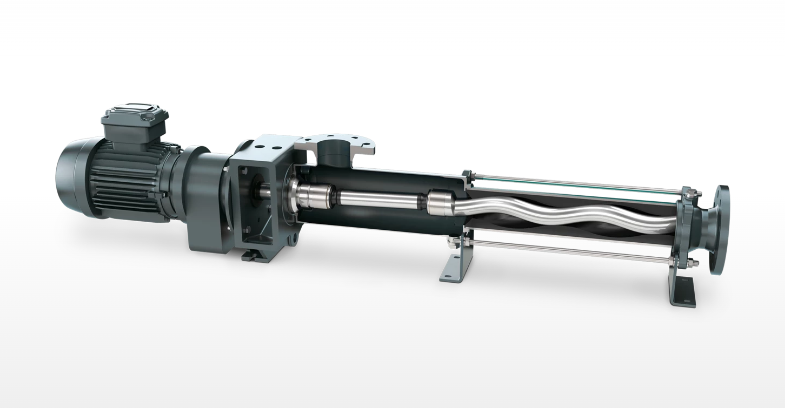

A Progressive Cavity Pump is a type of positive displacement pump, which consists of a rotor and stator. The metal rotor drives the stator through the chain and begins to fill the cavities with equal amounts of liquid which then get pushed through the pump outlet.

The rotor inside the pump rotates within the stator, as it turns, the cavities within the stator are filled with the process media and are carried towards the pump outlet under pressure. The pockets of fluid have a set volume that decides the volumetric flow rate of the pump, this is directly proportional to the rotational speed of the rotor and results in low levels of shearing and little to no pulse.

What is a progressive cavity pump?

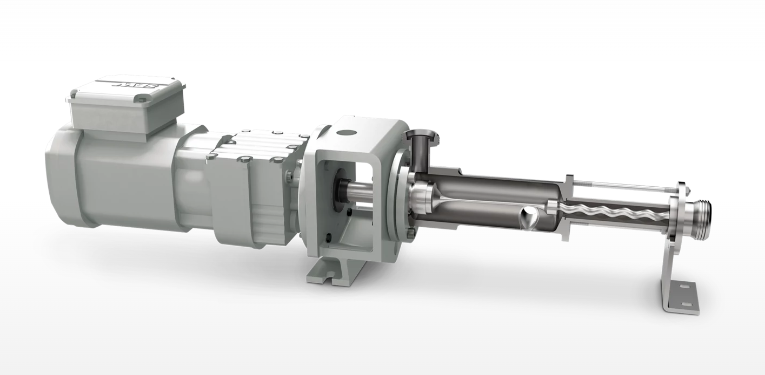

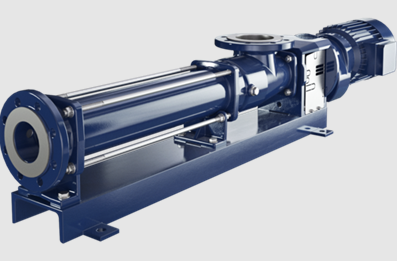

A progressive cavity pump, also known as a PC pump or a helical rotor pump, is a type of positive displacement pump. It consists of a helical rotor and a stator. The rotor has a unique shape, resembling a twisted screw, while the stator is a smooth cylindrical tube with an internal helical shape.

When the rotor rotates inside the stator, cavities are formed between the rotor and stator. As the rotor turns, these cavities progress from the suction side to the discharge side of the pump, hence the name “progressive cavity pump.” This movement creates a continuous flow of fluid through the pump.

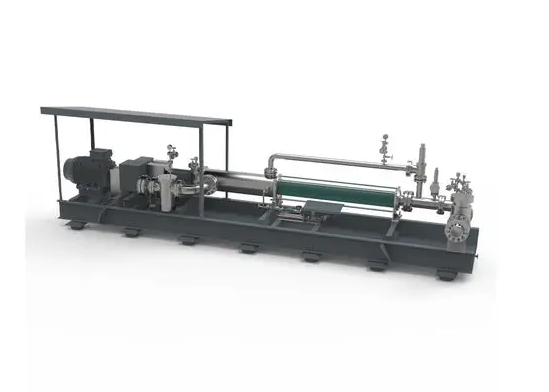

The progressive cavity pump is highly efficient in handling viscous and abrasive fluids, as well as fluids containing solids or fibers. It is commonly used in various industries, including oil and gas, wastewater treatment, food processing, and chemical manufacturing.